Copyright © Shenzhen Hesheng Vacuum Technology Co., Ltd. All Rights Reserved. Site Map

- +86-18129979970

- hvt-vacuumvalves@outlook.com

- Floor C, Building 3, Chuangye Road, Shilong Community, Shiyan Street, Baoan District, Shenzhen

Features: | Wide adjustable range of flow conductance spectrum Modular combination of different main valves and bypass valves |

Easily reproduce flow patterns and process settings Full functionality even under high voltage differential | |

Advantage: | Avoid turbulence and vacuum pressure pulses Large conductance range, precise regulation and calibration |

Long maintenance-free operation Minor maintenance can be performed quickly and easily | |

Nominal voltage DC voltage AC voltage |

|

24V | |

220V(Optional) | |

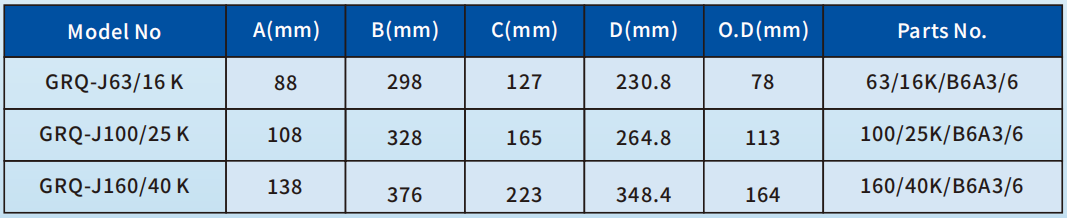

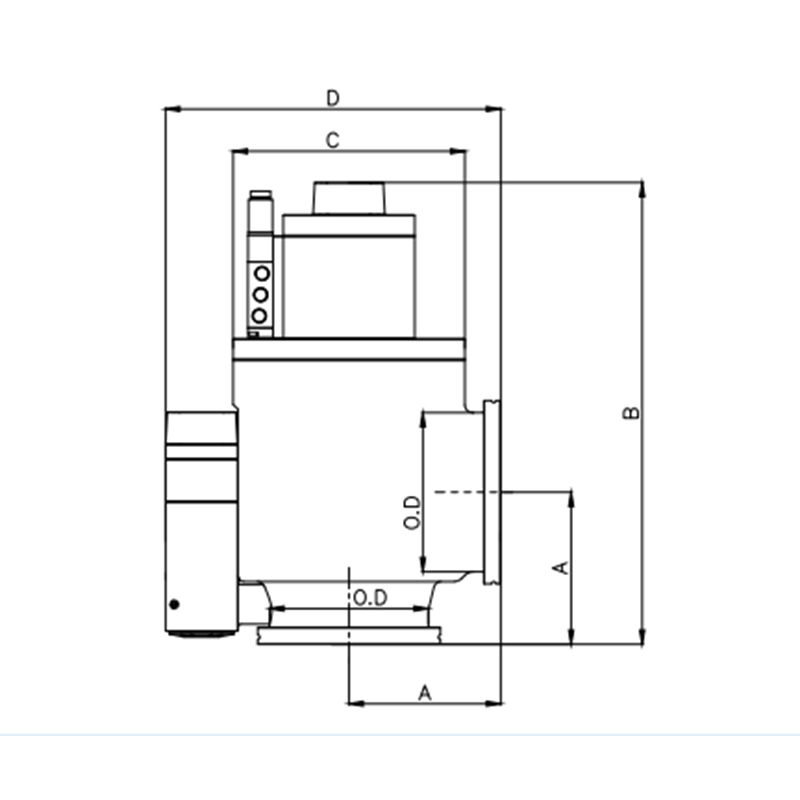

Vacuum flange interface | ISO-K63(DN16 bypass) ISO-K100(DN25 bypass) ISO-K160(DN40 bypass) |

Driver Driver Compressed air supply line size Pressure range | Open: Pneumatic |

Closing: Pneumatic (spring optional) | |

Ø6mm(Optional) | |

3.5~8x10⁵ Pa | |

Valve travel | 35mm 46mm 46mm |

Angle valve flow conductance Switching frequency Opening time Closing time | 5~ 165L/S 20~300L/S 50~850L/S |

<10/min <10/min <10/min | |

<0 .2s | |

<0 .2s | |

Service life | ≥500000 Second-rate |

Vacuum leak rate | 1x10⁻¹⁰Pa·m³/sec(1x10-⁻⁹mbar·L/sec) |

Maximum pressure inside the valve Minimum operating pressure inside the valve | 5bar(absolute) |

1x10⁻⁸mbar | |

Maximum operating pressure inside the valve Pressure differential range Closing direction Opening direction | 2bar |

Δp | |

≤5bar | |

≤2bar | |

Temperature Working environment Bake body Cylinder Driver Solenoid valve |

|

0℃~50℃ | |

≤150℃ | |

150℃ | |

150℃ | |

20~70℃ | |

Installation direction Flow direction | Any |

Any | |

Material Body Valve body Bellows assembly Spring Sealing ring Switch indicator box Visual position indicator Magnetic indicator (optional) |

|

| |

High-purity aluminum alloy (green low-carbon hydropower photovoltaic aluminum) | |

SUS 304/SUS 316L | |

Spring steel | |

FKM(fluororubber) | |

ABS/PC | |

OMRON Ohm's Dragon (lifespan more than 30 million times) | |

DMS | |

weight | 3.5kg 7.8kg 15.9kg |